DIGITALIZATION OF SERVICE ACTIVITIES

Manage and optimize service operations, from anywhere, anytime

SERVICE SOFTWARE

Integrated management of all service and maintenance resources and costs

Planning and allocating resources, monitoring and optimizing time and costs, as well as managing the equipment and stocks needed to provide services can be managed efficiently through a complete system dedicated to service activities. The solution is able to successfully cover both installation activities and types of maintenance, achieving optimal management of each work stage:

- Viewing works and teams based on a calendar

- Optimal route planning, based on different criteria

- Complete monitoring of works and costs involved

- Flexible invoicing based on estimates or real data

- Capacity to analyze data and make automated decisions

cpm

Complete budgeting of service activities

Maintenance companies need to have complete control over costs, human resources, spare parts and time allocation, while also being able to forecast future results. Analysis and budgeting solutions can help with detailed planning of service and maintenance activities, such as:

- Spare parts and material costs

- Labor and human resource estimates

- Purchases based on service and repair requirements

- Indirect and operating costs (ex.: transportation, logistics, taxes, staff training)

SERVICE MANAGEMENT

Gain full control over service operations, from planning to reporting

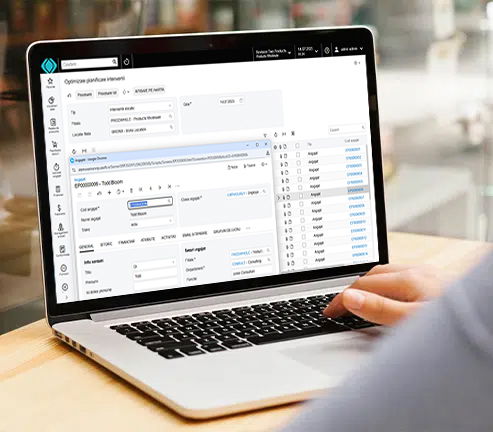

The service and maintenance solution can support every step of the service management process, from planning to reporting. The program combines service ticket management activities with advanced functionality for scheduling, monitoring and controlling field service tasks, making the necessary connections to optimize all operations.

Create new meetings and allocate resources for scheduled meetings

The service operations management solution includes an integrated calendar, which allows the creation, planning and allocation of resources in an intuitive and flexible way.

Features

- Schedule activities in the calendar, either automatically or by drag&drop

- View jobs and teams by day, week or month

- Create meetings and appointments directly from the calendar

- Assign resources and teams for each scheduled job

- Filter the calendar according to the specific requirements of each intervention

- Access relevant data, using various parameters, such as geographical area

Efficiently manage the maintenance operations schedule

The system allows the creation of appointments, automatically or using drag & drop tools in the intervention screen, by using colors to identify the status of each service order.

Features

- Resource allocation based on availability and skills

- Automatic updating of appointments for technicians and field teams

- Adjustment of appointments based on the level of urgency or priorities

- Allocation of interventions based on availability and complexity

- Establishing appointments according to the particularities of each case

- Automatic notification of customers and technicians regarding changes that have occurred

Optimally manage service and maintenance activities

The solution allows easy management of resource planning, ensuring the allocation of the most suitable people, at the right time and with the necessary skills.

Features

- Check the availability of resources (spare parts, equipment, etc.)

- Distribute technicians according to skills and schedule

- Automatic generation of work orders

- Monitor resource usage and planned activities

- Send notifications regarding changes or delays

- Automatic replanning of resources when priorities change

Optimally manage inventory for maintenance activities

Service operations require rigorous spare parts management, real-time inventory monitoring, and efficient integration between logistics and maintenance processes.

Features

- Manage spare parts inventory across multiple vehicles and warehouses

- Automatically generate purchase orders in case of stock shortage

- Check item availability at location level

- Automatically allocate parts for planned maintenance activities

- Synchronize inventory with maintenance and supply flows

- Access parts data and inventory status directly from your mobile

Improve the efficiency of interventions by optimizing routes

Graphical information about location, driving time and other relevant details are displayed immediately on the mobile device of the operator on the move, providing real-time access from anywhere.

Features

- Use Google Maps services for route planning and filtering

- Automatic update of orders and interventions directly on the mobile

- Add observations and recommendations regarding the condition of the equipment

- Send notifications to customers in case of delays or changes

- Monitor the position of the teams in real time on the map

- Record the routes traveled and travel times

Efficiently monitor field activities

During the intervention, the technician records the replaced parts and the operations performed in the application, and the data is saved in the system and can be accessed later for analysis or reporting.

Features

- Recording parts and materials used during the intervention

- Allocation of parts for each intervention, based on data on available stock

- Monitoring the time allocated for each operation or project

- Accessing technical documentation directly from the application

- Filling out digital forms for service reports and verifications

- Generating intervention sheets and tracking resource commitments

Ensure optimal performance through complete testing and validation

After completing the work stipulated in the contract, the technician completes the intervention report, mentioning the operations performed and the materials used.

Features

- Verifying the operation of the equipment according to technical parameters

- Assessing the behavior under limit or failure conditions

- Presenting a demonstration of use to the customer

- Confirming compliance with quality, security and compliance standards

- Managing internal approvals and confirming the work by the customer

- Completing the intervention report with details about the operations performed

- Recording customer feedback and integrating it into the intervention history

Improve customer experience through the integrated self-service portal

The portal allows customers to report incidents, view and download invoices, and all requests are automatically taken over by the ERP system for fast and efficient management.

Features

- Automatic recording of incidents reported by customers in the ERP system

- Automatic assignment of requests to the responsible teams

- Tracking the status of requests and automatic updating of information

- Secure access to data about contracts, invoices, payments and intervention history

- Centralized management of notifications and complaints in the ERP platform

- Archiving and complete traceability of communications and interventions

- Integration of the portal with the service and billing modules in the system

- Control of access rights for users on the customer side

Simplify the billing process for services provided

After completing the activity, the finance department intervenes to generate the invoice based on the services provided, which is sent to the client by email or available in the client portal.

Features

- Generate invoices based on actual or estimated costs

- Associate invoices with intervention reports and service orders

- Record supplier invoices related to field activities

- Define automatic billing rules

- Automatic calculation of taxes according to defined policies

- Integration with accounting and payment modules

- Automatic update of invoice status and balances

- Send invoices by email or client portal

Clients

MOBILE APP

Mobilizes field teams for fast, accurate and transparent interventions

Available on both IOS and Android platforms, the mobile application offers capabilities that allow more efficient field activity and increase customer satisfaction by quickly and accurately resolving submitted requests.

- Efficient distribution of service team tasks

- Quick access to intervention history and documentation

- Automatic generation of performance reports

- Synchronization with other platforms for an optimized flow

- Operation and saving of data without an internet connection

- Protection of information through secure authentication

WHAT CLIENTS SAY

Frigotehnica - leader in the refrigeration equipment market in Romania

We operate in approximately 1300 locations, and the complexity of the applications developed generated the need for process automation. The main benefit of implementing Senior Software is that we have real-time visibility on the areas where we need to intervene, on projects, on uncollected and overdue invoices.

Adina Cotiga

PROACTIVE AND REACTIVE MAINTENANCE

Intelligent, integrated service adapted to your industry

Whether interventions are carried out on-site or through remote support, the service and maintenance system allows for the automation of technician allocation and preventive scheduling, real-time monitoring of equipment and spare parts, as well as the rapid generation of reports. In addition, it contributes to reducing costs and ensuring strict compliance with standards and contractual obligations.

- Equipment & machinery

- Construction

- Installations

- Distribution and logistics

- IT & technology

- Automatic allocation of available technicians based on location and competence

- Scheduled maintenance and periodic inspections, generated according to the established preventive maintenance plan

- Real-time access to spare parts stocks and fast delivery to the intervention site

- Complete management of the RMA (Return Merchandise Authorization) flow, from registration to repair completion

- Automatic tracking of returned equipment statuses

- Efficient workshop capacity management, with the allocation of resources and necessary parts based on availability

- Remote technical diagnostics, via phone or customer portal, for rapid problem triage and avoiding unnecessary trips

- Service tickets with defined SLAs, access to the complete equipment history and integrated technical documentation

- Automatically generated post-intervention reports, with hours worked, parts used, costs, etc.

- On-site troubleshooting for faulty equipment, with automatic location of the equipment and rapid allocation of the intervention team

- Optimal allocation of the service team, depending on the location of the site, staff availability and technical skills

- Stock updated in real time, correlated with the route and interventions of the technicians

- Automatic orders for mandatory periodic inspections (internal ITP, hydraulic, electrical systems, etc.)

- Automatic scheduling of technical checks, according to legal requirements (ISCIR, PSI regulations)

- Automatic notifications for repairs and periodic inspections

- Monitoring of faulty tools withdrawn from the site and their re-entry into circulation

- Complete record of consumables, replaced parts and equipment downtime

- Service history integrated into the sheet of each equipment, accessible in real time

- Automatic scheduling of mobile teams for interventions, based on proximity, availability and technical skills

- Check-in/Check-out at the customer's location, with automatic generation of the intervention report transmitted instantly

- Access to equipment history and automatic reservation of spare parts

- Preventive maintenance planning (e.g.: spring/fall for HVAC, seasonal checks for thermal, sanitary or BMS systems)

- Record of contractual obligations (visits, SLA, equipment), with alerts for delays or deviations

- Automatic generation of work sheets, with predefined activities according to contract, equipment and location

- Mobile application with access to documentation, photos, used parts, etc.

- Dashboards for monitoring interventions, teams, etc.

- Integration with customer systems (e.g.: Building Management Systems) for automatic receipt of alerts

- On-site service for handling equipment (conveyor belts, forklifts, hydraulic lifts, etc.)

- Technical support for IT picking and scanning equipment (barcode readers, mobile terminals, label printers)

- Maintenance for installed logistics infrastructure (smart shelves, automated internal transport systems)

- RMA management for defective equipment returned by customers (full flow: registration - diagnosis - repair - return)

- Warranty monitoring of equipment sold, with alerts for warranty expiration and possibility of extension

- Digital documentation associated with products sold: technical sheets, service instructions, intervention history

- Automatic reservation of spare parts associated with the product directly from the equipment sheet

- Automatic ticket generation based on reported incidents

- Rapid allocation of IT technicians for physical interventions or equipment exchanges

- Complete management of equipment located at the customer's premises

- Integrated ticketing and SLA management module for incidents, requests and changes

- Possibility of reporting technical support activity provided remotely via phone, email, mobile application or remote desktop

- Automatic planning of recurring IT maintenance (software updates, patch management, security checks)

- RMA management for IT equipment under warranty or lease

- Record of software licenses and notifications for expirations or renewals

- Automatic reporting for SLAs, average response time and costs per ticket or customer

- Mobile application with access to equipment sheets, documentation and incident history

MAINTENANCE

Efficiently carry out maintenance and overhaul plans for each piece of equipment you own

In terms of maintenance types, the system covers installation activities and ensures efficient management of each work stage. The software solution coordinates maintenance schedules and repair requests for faults, while monitoring the spare parts used for each installation or equipment.

Preventive maintenance

- Detection of deviations before failures occur

- Planning of inspections, tests and parts replacements

- Establishing a maintenance plan for each machine

- Programmed interventions to prevent damage

Corrective maintenance

- Rapid identification of failures and allocation of repair activities

- Operational remediation to resume normal operation

- Efficient management of necessary resources

- Resuming processes before critical situations occur

Autonomous maintenance

- Simple maintenance operations: visual / sensory inspections

- Failure prevention through operator involvement

- Operators are responsible for cleaning and inspection

- Accuracy verification and other maintenance activities

Predictive maintenance

- Predicting the possible moment of equipment failure

- Monitoring equipment through analyzed parameters

- Early detection of defects for strategic planning

- Proactive actions to avoid possible damagei

ANALYTICS & DASHBOARDS

Monitor and evaluate the performance of service activities

Monitoring business progress and identifying critical situations in the market or organization in time are essential for the future of the company. The system transforms raw data into easy-to-view and understandable information, providing a clear picture of the business and the ability to react promptly, whenever necessary.