LOGISTICS

WMS Software

WAREHOUSE MANAGEMENT

Automate warehouse processes with the WMS system!

Suitable for any industry, the WMS solution from Senior Software allows for efficient management of goods, from their reception to the preparation of orders and their delivery to the customer.

WMS automates warehouse activities and optimizes storage space, offering multiple functionalities, designed to increase employee productivity. The system transforms and organizes the way warehouses work, ensuring complete traceability and rapid adaptation to internal and external business changes.

- 100% traceability

- 99% inventory accuracy

- 98% correct deliveries

- 60% reduction in returns

WAREHOUSE MANAGEMENT SOFT

Optimize logistics activities with the WMS software system adapted to your business

The WMS solution is developed on an internationally recognized platform and adapted to the particularities of the local business environment. Successfully used by hundreds of companies, the system has a set of unique features, essential for the management of logistics operations:

Customizable

Integrated

Scalable

Multilingual

WHAT CUSTOMERS SAY

Vitacom can process up to 10 times more orders with the help of the WMS system

The current technology we work with is much more flexible, has many more features and responds very well to our needs, because we no longer say that we need this and that and something should be developed, but simply, settings are made in the application and that helps us a lot.

Vasile Andrei Vita

SYSTEM FEATURES

The WMS solution successfully covers all essential warehouse activities!

WMS (Warehouse Management System) allows a high degree of automation in warehouses. The solution incorporates the latest technologies with which warehouse operations (lifting, sorting, storage, retrieval, etc.) are simplified, picking times are improved, and human errors are considerably reduced. Thus, data and orders are processed correctly, and employees become more productive.

Optimizes the movement of goods within a warehouse

WMS asigura trasabilitate completa asupra marfurilor si permite gestionarea eficienta si in timp real a tuturor activitatilor cu privire la miscarea acestora in cadrul depozitului.

Features

- Multi-tenancy support

- Intelligent logistics attributes

- 2 levels of stock allocation

- Advanced traceability of the entire logistics flow

- Stock movement management

- Barcode and labeling management

- Product kit management

- Support for multiple packaging types

Efficiency of the entire goods receiving process

The WMS solution automates the activities aimed at managing inbound, receiving and returning goods, while also offering complete support for cross-docking operations.

Features

- Manual or task-based receiving

- Purchase order management

- Returns management

- Management of goods accompanying advice

- Advanced shelf arrangement scenarios

- Cross-docking operations

- Notifications regarding goods received

- Item labeling and classification

Transform and organize the way you work in the warehouse

Processing customer orders along with stock allocations, managing picking activities, but also sorting, packaging, consolidation and loading operations, can be done with the WMS system.

Features

- Different activity flows depending on the type of order

- Standard or advanced inventory control rules

- Packing according to different algorithms

- Sorting according to order/stock

- Multiple loading methods (per order, delivery route, etc.)

- Picking (discrete, consolidated, wave picking, pick-to-cart, zone picking, etc.)

- Goods labeling and AWB generation

- Integration with courier software

Complete visibility into ongoing tasks

Through the warehouse control center, WMS tracks the activity of all warehouse operators, while also managing tasks efficiently.

Features

- Manual or automatic task allocation

- Real-time visualization of task execution mode

- Task allocation based on proximity

- Establish execution rights at employee level

- Identify bottlenecks and execution times

- Generate productivity reports per employee

- Monitor goods movements

- Prioritize tasks according to different criteria

Improve the performance and accuracy of warehouse processes

WMS facilitates the evaluation of operational performance, identification of improvement opportunities and implementation of effective strategies for optimizing warehouse workflows.

Features

- Real-time tracking of mobile device users

- Real-time monitoring of executed tasks

- Real-time updated dashboards

- Detection of bottlenecks and optimization recommendations

- Visual representation of storage locations

- Communication capabilities with warehouse employees

- Analysis of warehouse-specific KPIs

- Automatic performance reports

Latest Technology for Logistics Performance

Voice-guided systems, combined with touch screens, maximize the accuracy of picking operations and increase the productivity of teams using WMS software.

Features

- Directional lighting systems

- Voice-guided or hands-free systems

- Automated storage and retrieval systems

- Digital warehouse control

- RFID technology

- FIFO/FEFO unloading

- Automatic Inventory

- Upstream and downstream traceability

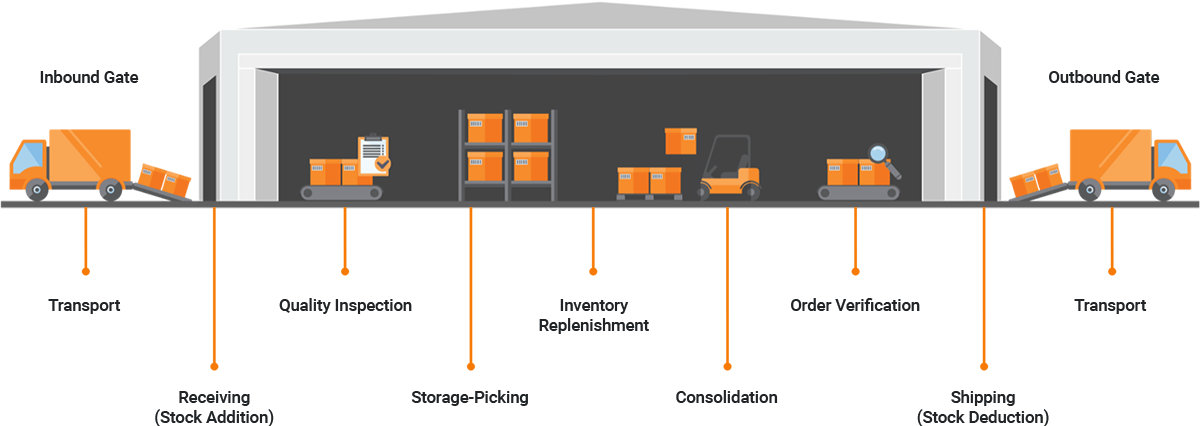

WAREHOUSE OPERATIONS

How is warehouse flow automation done?

BENEFITS

What are the benefits that the WMS solution offers?

The profitability of a company is closely linked to the intelligent use of resources, efficient activities, correct information, satisfied customers and careful and constant monitoring of the warehouse situation. So, here are some ways in which the WMS solution contributes to increasing profitability:

Minimizing warehouse

Reducing delivery time

Increasing employee productivity

Complete visibility

Optimal use

Complete traceability

Rapid integration

Increasing customer

RESULTS

Maximum warehouse performance with WMS!

30 %

storage space optimization50 %

reduced inventory times35 %

increase in productivity35 %

increase in deliveries82 %

fewer material losses26 %

reduced logistics costs

INDUSTRIES

The right software solution for any industry

- 3PL / 4PL

- Retail

- E-commerce

- Production

- Distribution

- Manages multiple sales channels simultaneously

- Maximizes the use of staff and optimizes the storage space

- Flexible invoicing: eliminates hidden costs, highlighting hard-to-identify fees

- Cross-docking: reduces costs and space

- Return adaptability: the best performing reverse logistics management system

- Warehouse intelligence to increase efficiency and improve decision-making process

- Parcel management and partial truck transportation

- Manage multiple sales channels simultaneously

- Maximizes the use of staff and optimizes the storage space

- Packaging and labelling to support marketing and sales actions

- Upstream and downstream traceability with warehouse WMS software

- Parcel management and partial truck transportation

- Payment on delivery to stimulate sales and improve cash flow

- Processing orders from e-commerce

- Intelligent logistics attributes – unlimited, related to items, stocks, orders, recipes

- Cross-docking operations for difficult products

- Allocation of level 1 stocks by reservation of products ordered by customers

- Different picking methods depending on the type of products and the purpose pursued

- Automation of order preparation processes: pick-to-cart; pick-to-light; pick-by-voice

- Integration of RFID technology for automation of warehouse activities

- Integration with materials handling automation systems

- Advanced order packaging and label printing systems

- Parcel management and partial truck transportation

- Efficient return management, along with return reasons and printing of return labels

- Integration with other ERP and WMS systems, interfacing with marketplaces, data import and export

- A large number of items with different destinations can be traced: finished products, raw materials, semi-finished products, packaging

- Optimal use of storage space

- Optimization of material flow within the plant

- Automation and monitoring of quality control processes

- Batch tracking, consumption and production efficiency

- High accuracy of the product recall process

- Cross-docking to reduce costs and space

- Upstream and downstream traceability

- EDI integration to maximize visibility in relation to partners

- Maximizes the use of staff and optimizes the storage space

- Advanced rules for unloading management: FIFO/FEFO

- Upstream and downstream traceability

- Repackaging and labelling, according to customer requirements

- High standards for frozen products

- Quality control of goods

- Integration with our solution for inventory planning and optimization

- Possibility to control the network of partners

- Automated stock allocation according to IKA delivery rules